By reducing wear and increasing efficiency, adjusting belt alignment considerably increases machinery service life and decreases power usage. Although you can locate misalignment visually or with a straight edge, identifying angular, vertical, and horizontal misalignment is considerably quicker and easier with a pulley alignment laser tool. In addition, our pulley alignment and laser belt alignment technologies are simple to use and can pay for themselves in as little as a few months. It is simple to increase service life with proper alignment. Whichever of our tools you decide to use for belt transmission alignment typically pays for itself in months.

The Benefits Of Laser Technology Over Conventional Technology

Working with lasers is quicker and simpler than working with cables and rulers. To use these techniques, two individuals are typically needed: one to hold the ruler and the other to adjust the machine. These approaches are arbitrary and depend on who is doing the alignment, making it impossible to detect minute variations with the human eye. Systems for measuring with lasers are much simpler to interpret. They are also far more accurate. For optimum service life and effectiveness, it is occasionally advised by the belt manufacturer that there be a maximum angle inaccuracy between the pulleys of 0.5 to 0.25 degrees. Without a laser, such tiny angles are invisible to the human eye.

What Are The Primary Advantages Of Laser Use?

- Your outcomes are more trustworthy and are less influenced by the human element. This is especially true for digital tools unaffected by the engineer’s vision.

- You can record the outcomes and demonstrate that they meet both the machine manufacturer’s requirements and the applicable ISO standards for your business. A type of quality control.

- It is easier, quicker, and more effective than conventional techniques. In other words, when belts are replaced, there is a higher likelihood that alignment will be done correctly.

- One person can complete the alignment if necessary.

- A cheap investment that pays for itself rapidly, partially through lower energy use.

Why is Proper Belt Alignment So Important, Then?

These are some of the issues that may develop if belts are even slightly out of alignment:

- A lot of vibration

- premature component wear and tear

- Seals that leak

- failing a bearing

- increased energy use

- Equipment failures

- Unexpected, high-cost maintenance and downtime

- delays and losses in production

- Unpleasant and noisy workplace

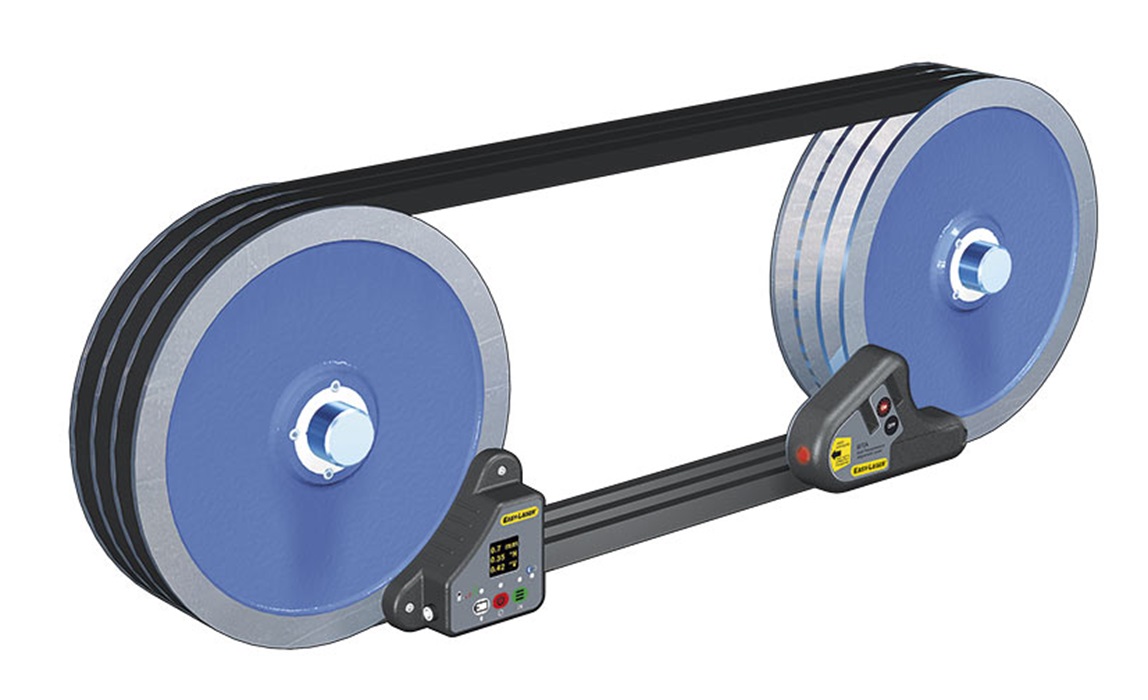

Transmissions with many broad, wide belts or multiple belts that are more numerous than one are especially vulnerable to misalignment issues. The machine’s efficiency will be reduced if the inner and outer belts are not tensioned or driven uniformly, and as soon as one belt wears out, all the belts must be replaced, which raises costs. Misalignments also influence sheaves and pulleys. This simple-to-use but very sophisticated equipment employs strong laser beams to automatically compute the alignment of pulleys, belts, stringers, idlers, conveyors, and other components with exact accuracy, in contrast to conventional systems that rely on manual operation using strings or rulers. In addition, the technology captures the data and generates a thorough report outlining the required adjustments.

Mounting on the Side for Greater Accuracy

When aligning the pulley, Easy-Laser® uses the side surface as a reference. Due to the tool’s wider mounting area compared to when it was mounted against the radial surface results in improved precision. The outcome on the side is less affected by any pulley flaws and damage (see image). The pulley is obviously more vulnerable to wear and corrosion in and around the groove where belts flow. Another benefit is that, regardless of the belt type, all pulley types can be aligned without needing additional equipment. Even adjusting for pulleys with different widths is simple. The equipment may be mounted thanks easily to magnetic mountings on lasers, detectors, or targets.

What Techniques Are Most Commonly Used to Align Belts and Pulleys?

Hand instruments like a feeler gauge or straight edge, belt alignment system or a laser pulley alignment tool are the most often used techniques for aligning belts and pulleys.

We are the Master Easy-Laser Distributor in Canada. For additional details about our belt alignment tools, get in touch with us.